In recent years, Vietnam has rapidly emerged as a leading manufacturing hub, particularly in the sheet metal fabrication industry. Its competitiveness in this sector stems from several compelling factors that can significantly reduce production costs for businesses. We’ll explore these cost-saving benefits across three key dimensions: financial, location-related, and quality & innovation.

Financial Advantages

Competitive Labor Costs

Vietnam’s labor costs are much lower than those of many developed nations. The World Bank reports that in 2022, Vietnam’s manufacturing workers earned an average monthly wage of $280, while in the United States, it was $4,000. This low cost, along with a larger pool of capable workers, allows businesses to significantly reduce labor expenses.

Attractive Tax Incentives

The Vietnamese government actively encourages foreign investment through a range of tax incentives. These include less corporate income tax, no import duties, and special economic zone benefits. For example, the 2020 Investment Law provides corporate income tax exemptions for up to 4 years and a 50% tax reduction for up to 9 subsequent years for qualifying projects.

Location Advantages

Strategic Geolocation and Supply Chain Optimization

Vietnam’s location in Southeast Asia provides easy access to major global markets. Its proximity to key shipping routes ensures efficient and cost-effective transportation of goods. Vietnam is a member of the ASEAN Free Trade Area (AFTA), which offers preferential trade terms with other ASEAN member countries.

Expanding Infrastructure

Vietnam is investing heavily in modernizing its infrastructure, including roads, ports, and logistics facilities. This ongoing development supports the manufacturing sector and ensures smooth and uninterrupted movement of goods. The Ministry of Planning and Investment reports plans to invest $120 billion in infrastructure development between 2021 and 2025.

Quality and Innovation

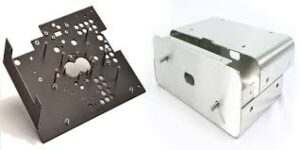

High-Quality Production

Vietnamese manufacturers have also gained a reputation for producing high-quality sheet metal products. They adhere to international standards like ISO 9001:2015 certification, ensuring that their products meet the rigorous demands of global markets.

Focus on Technology and Training

The Vietnamese government is promoting innovation and technological advancement in the manufacturing sector. Companies are investing in modern technologies and training programs to improve product quality and production efficiency.

Conclusion

In conclusion, manufacturing sheet metal products in Vietnam offers numerous advantages, including cost savings, government incentives, strategic location, and a commitment to quality and innovation. As the country continues to develop its manufacturing capabilities, it is poised to become a leading player in the global market. Click here to contact us for a conversation on how we can help you achieve improvements on your contract manufacturing assignments.