Laserhub Asia Sheet Metal – Sheet Metal Fabrication at our factories in South East & West Asia

Online Quotation Portal. Calculate prices yourself!

We are Laserhub Asia

Laserhub Asia Sheet Metal Fabrication is a Western-operated metalworking organization with wholly owned manufacturing facilities strategically located across Asia, including India, Vietnam, Indonesia, and Malaysia. We specialize in precision sheet metal fabrication, offering a broad range of services with a strong focus on laser cutting technologies as a core element of our production process. Our operations are built to serve industrial customers seeking reliable, high-quality, and tariff-conscious sourcing solutions for metal components.

Operations

Our production capabilities cover the entire sheet metal fabrication value chain, including laser cutting, bending, welding, surface finishing, and assembly. By maintaining direct ownership and control over our factories, we ensure consistent stability, quality assurance, and delivery reliability across all locations. This infrastructure allows us to shift production flexibly between sites based on customer-specific criteria such as lead time, cost targets, technical complexity, or trade exposure.

Tariffs and optimization

Laserhub Asia Sheet Metal is uniquely positioned to support international customers requiring tariff-optimized manufacturing strategies. Our integrated supply network is designed to create supply chain profiles that comply with country-of-origin requirements and take full advantage of preferential trade agreements where applicable. This includes minimizing the impact of U.S. and EU tariffs through careful production routing, material sourcing, and documentation practices — a critical factor in today’s global trade environment.

Professionals from the West and the East

The organization is led by European industry professionals with extensive operational experience in managing sheet metal production facilities across both Europe and Asia. Our leadership team brings decades of technical, managerial, and strategic expertise, ensuring that our operations meet high Western standards of quality, compliance, and process discipline. Each facility operates with trained and experienced local workforce, capable of executing both simple and complex fabrication projects with precision and consistency.

The need for well developed production capacity

In recent years, the demand for industrial laser cutting and advanced fabrication in Asia has grown rapidly, driven by the need for scalable, environmentally conscious, and highly accurate manufacturing processes. Laser cutting offers key advantages in terms of material efficiency, repeatability, and edge quality — all critical parameters for customers requiring tight tolerances and reliable performance.

How Laserhub Asia Sheet Metal Can Help You

At Laserhub Asia, we serve a wide range of industries including electronics, machinery, construction hardware, enclosures, and transportation; we do this through OEM manufacturing and. Our service offers spans creating samples, high-volume contract manufacturing assignments, and custom fabrication projects. Our operational model allows us to align closely with client design requirements, regulatory constraints, and commercial expectations across regions.

Whether you are seeking to develop a multi-supplier strategy in Asia, reduce risk in your existing supply base, or shift production out of China for strategic or regulatory reasons, Laserhub Asia provides the technical depth, infrastructure, and international competence to meet your goals.

Contact us now to discuss sheet metal contract manufacturing, sheet metal fabrication, or OEM production.

Metalworking operations at Laserhub Asia Sheet Metal

Laser cutting service

Our laser cutting capabilities deliver high-precision components with clean edges and tight tolerances. Using advanced CNC laser cutting systems, we handle a wide range of metals including stainless steel, aluminum, and carbon steel. Whether for prototyping or full-scale production, we ensure consistent quality and efficiency across batch sizes.

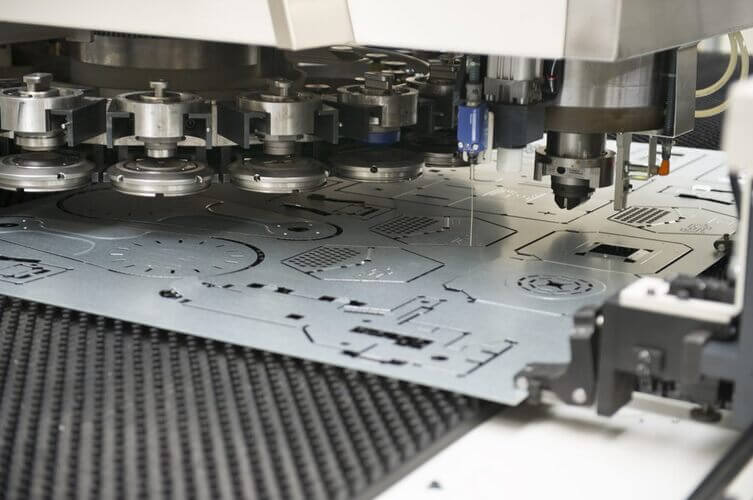

Turret punching

Equipped with CNC turret punch presses, we offer fast and flexible punching of complex sheet metal geometries. Our turret punching operations support a variety of tool configurations, enabling rapid turnaround on parts with holes, slots, louvers, and other forms. Ideal for medium to high-volume production, our process optimizes material utilization and repeatability.

Stamping

We provide both progressive and single-hit metal stamping services to meet diverse production requirements. With tooling designed for high-speed accuracy, our stamping operations are suitable for everything from automotive brackets to consumer electronic housings. Stamping offers a cost-effective solution for high-volume runs with consistent part quality.

Bending

Our precision press brakes enable complex and accurate bending operations across a variety of sheet metals. Skilled technicians and automated setups ensure consistent angles, radii, and form integrity — even on multi-bend parts. This makes our bending process suitable for enclosures, brackets, and custom assemblies with tight tolerance requirements.

Welding TIG/MIG

We offer expert manual MIG and TIG welding services for ferrous and non-ferrous metals. Whether it’s structural steel or delicate aluminum components, our certified welders ensure joint strength, visual quality, and durability. MIG welding is ideal for thicker materials and faster throughput, while TIG offers superior precision for complex or aesthetic welds.

Robot laser welding

Our robotic laser welding systems increase productivity and consistency in high-volume production runs. Programmed for precision and repeatability, robotic MIG and TIG welding is perfect for structural components, frames, and repetitive assemblies. Automation minimizes defects and ensures each weld meets stringent quality standards.

Surface finishing

To enhance both aesthetics and corrosion resistance, we provide a range of surface finishing options including powder coating, anodizing, galvanizing, and polishing. Each finish is tailored to your material and performance needs, ensuring your parts not only function perfectly but also meet your visual and durability expectations.

Assembly

Beyond fabrication, we offer mechanical and electromechanical assembly services to deliver complete subassemblies or finished products. Our assembly lines are equipped for component integration, fastener application, and functional testing, helping you reduce in-house labor and streamline your production pipeline.

Packing

Our packing operations ensure products are safely protected for transit and meet customer-specific logistics requirements. We provide custom packaging solutions, labeling, barcoding, and kitting services, ensuring traceability, damage prevention, and cost-effective shipping — whether it’s local delivery or international export.

Serving a Diverse Range of Industries with Metalworking Solutions

At Laserhub Asia, we specialize in delivering high-quality metal components and assemblies across a wide range of industries. From precision machine parts to infrastructure for solar energy and electric vehicles, our flexible manufacturing capabilities and engineering expertise allow us to serve clients with diverse technical and commercial requirements. Whether it’s a high-volume production run or a tailored OEM solution, we combine efficiency, durability, and attention to detail in everything we produce.

Housing and Paneling

We have produced housings and paneling on an OEM basis for automation systems, machinery, and mechanical assemblies. Manufactured to customer specifications using durable and robust materials, these components were built to perform reliably under demanding industrial environments.

Electrification & mobility

Through contract manufacturing assignments, we have supplied structural and protective sheet metal and die-cast components for EV charging stations. Our production scope has included frames, brackets, housings, and enclosures — tailored to ensure long-term performance.

Food processing

We have manufactured stainless steel components for food processing and packaging equipment, meeting strict hygiene and corrosion resistance standards. These components have been used in conveyors, mixers, and machinery across industrial food production facilities.

Display products

On behalf of clients in the retail and digital sectors, we have produced display frames, kiosk structures, and digital signage supports. Our clean, precision-finished metalwork has enhanced product presentation and endured high-traffic environments, and surface treatments applied.

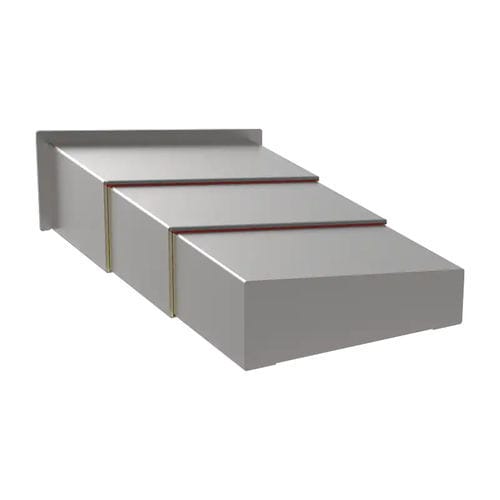

Enclosures

We have fulfilled OEM production contracts for enclosures designed to protect electrical and control systems in both indoor and outdoor environments. These units were made in diverse form factors and finishes to meet client specifications and regulatory safety standards.

Frames for furniture

As part of contract manufacturing engagements, we have supplied structural frames and support components for commercial and industrial furniture. Our output has combined strength, aesthetics, and cost-efficiency for applications such as seating, desks, and shelving systems.

Accessories for vehicles

We have produced a range of metal components and accessories for motorbikes, cars, and utility vehicles under OEM and aftermarket assignments. These include racks, mounts, guards, brackets, and structural frames — all developed in accordance with customer requirements.

Construction hardware

Under contract manufacturing agreements, we have delivered components for architectural and structural use, including fixtures, fasteners, brackets, and systems for doors and windows. These products were designed to meet both functional and aesthetic demands.

Mounting – audio/tv

We manufacture parts such as brackets, mounts, and structural supports for audio-visual equipment including speakers, amplifiers, and TVs. Our production focused on vibration control and surface finish quality to match the needs of high-performance electronics brands.

Handling solutions

We supply heavy-duty frames and platforms for trolleys and carts used across logistics, retail, healthcare, and manufacturing industries. Built for contract clients, these components emphasized ergonomic design, load-bearing strength, and long-term durability.

Motorbike accessories

Through OEM and contract manufacturing projects, we produce stamped, bent, and welded motorbike parts — including footrests, crash guards, accessory brackets, and frame components. Our focus has been on achieving optimal strength-to-weight ratios and corrosion resistance.

Renewable energy

We deliver metal mounting systems, brackets, and support frames for ground and rooftop solar installations. Manufactured as part of solar industry supply chains, these components durable, easy to install, and resistant to harsh environmental performance conditions.

Request for a quote

Why Laserhub Asia – Why should you work with us?

Direct, Simple, and Concise Communication, 2) Transparent Processes with Live Video Feeds to See Your Products Being – With Instant Quote Calculation

We are a foreign-owned enterprise that eliminates miscommunication by providing clear timelines and transparent insights into what can and cannot be done. No surprises – just reliability.

What sets us apart?

- Multilingual Support: We speak Dutch, German, English, and Vietnamese fluently – ensuring seamless communication across teams and borders.

- Global Expertise: With over 25 years of experience in sheet metal manufacturing across Europe, the USA, and Vietnam, we bring international standards to every project.

- Competitive Pricing: Our lean organizational structure keeps overhead low, allowing us to offer highly competitive hourly rates.

- Reliable Processes: We combine ERP systems with Industry 4.0 automation right from the start. We execute every job with thorough preparation – including detailed work, assembly, and coating instructions.

- Quality at Every Step: At Laserhub Asia we integrate quality control throughout the entire process. Using ERP software, we monitor, manage, and correct operations in real time – reducing waste and increasing efficiency.

Online Quote Portal

Want to know the cost upfront? Use our online portal with built-in calculation software to generate your own quote instantly. Just enter your specifications and receive a tailored cost estimate based on real production data – no waiting, no assumptions.