Explore Our OEM Product Categories:

Our portfolio of industries we have served

Industrial Carts and Transport Trolleys

These are material handling solutions designed for industrial environments such as factories, warehouses, and logistics hubs. Typically made from mild or stainless steel, they require structural integrity, ergonomic design, and high load-bearing capacity. Fabrication includes welding, precision bending, and powder coating for durability. Custom features of these sheet metal products often include locking casters, reinforced frames, and modular shelving to meet operational workflows.

Protective Enclosures and Electronic Housings

These sheet metal enclosure components are fabricated to shield sensitive electronic assemblies from environmental hazards, mechanical impact, and electromagnetic interference. Materials used include galvanized steel, aluminum, and stainless steel with options for EMI/RFI shielding. Precision laser cutting and CNC bending ensure tight tolerances, while gasketing, venting, and IP-rated sealing options support various industrial and outdoor use cases.

EV and Electrical Sheet Metal Products & Components

OEM metal components for EV charging systems and electrical infrastructure must meet strict electrical safety, corrosion resistance, and mounting requirements. Products include mounting brackets, cable trays, connector enclosures, and structural housings. These are often die-cast or laser-cut and powder coated to withstand outdoor exposure, vibration, and high electrical loads in compliance with IEC and UL standards.

Indoor and Outdoor Metal Frames for Furniture

These sheet metal products are fabricated furniture frameworks that serve as the structural backbone for residential, commercial, or hospitality furniture. Indoor versions prioritize finish aesthetics and minimal tolerances, often using aluminum or powder-coated steel. Outdoor variants require weather-resistant materials like stainless steel or hot-dip galvanized steel. TIG welding, surface grinding, and anti-corrosive coatings are essential finishing steps to ensure performance and longevity.

Solar Panel Hardware

Hardware for solar panels includes mounting rails, clamps, support brackets, and tilting frames for photovoltaic systems. These components are engineered to handle dynamic wind loads, thermal expansion, and long-term UV exposure. Fabrication often involves aluminum extrusion cutting, CNC drilling, and anodizing or galvanizing for corrosion protection. Compatibility with roofing systems or ground-mounted arrays is essential, and components often follow standards like UL 2703 or IEC 61215.

Precision Aftermarket Components for Cars, Trucks, and Two-Wheelers

Aftermarket OEM and contract manufactured vehicle accessories; These include custom brackets, guards, pedal kits, skid plates, and aesthetic trims designed for aftermarket upgrades. They must meet tight dimensional tolerances and mechanical strength requirements, often adhering to ISO/TS 16949 or local road safety regulations. Machining, deburring, shot-blasting, and surface anodizing or painting are typical finishing methods. Fixtures and jigs ensure repeatability in mid- to high-volume production.

Display Frames, POS Kiosks, and Digital Signage

These metal display structures house electronics, screens, and retail interfaces. These sheet metal products require high precision, smooth surface finishes, and integration features such as screen mounts, cable management, and cooling ventilation. Fabricated from cold-rolled steel or aluminum, they undergo laser cutting, bending, welding, and powder coating. Emphasis is placed on aesthetic appeal, vandal resistance, and ease of assembly in the field.

Construction Hardware

The category of construction hardware includes metal brackets, fasteners, joint plates, and structural reinforcements used in residential, commercial, and industrial building applications. Strength and compliance with standards like ASTM or EN 1090 are crucial. Products are made through stamping, forging, or CNC machining, followed by hot-dip galvanizing or epoxy coating to prevent rust in harsh construction environments.

Products and Industries; welcome to a diverse experience of Sheet Metal Products

Since its establishment, Laserhub Asia has served a wide range of industries through OEM and contract manufacturing solutions. With production hubs in Vietnam, India, Malaysia, and Indonesia, our flexibility and commitment to quality allow us to deliver precision sheet metal components for diverse applications—from machine casings to parts for solar energy systems.

Industries We Serve and What We Deliver

Industry sectors we work with

At Laserhub Asia, we manufacture high-quality sheet metal products using a wide scope of technologies, from laser cutting to welding and surface finishing. Our expertise spans automation systems, EV charging infrastructure, solar power components, and more. We also support sectors like retail displays, industrial kitchens, consumer electronics, furniture, and vehicle components—including carts and trolleys—with tailored solutions for every use case. Talk to us for more information.

Optimized Production Starts with Strong Preparation

Our deep experience across industries has sharpened our capabilities in New Product Introduction (NPI) and industrial work preparation. These strengths ensure that from the first prototype to full-scale manufacturing, every detail aligns with your technical and quality goals. Laserhub Asia specializes in transitioning designs into reliable mass production quickly and efficiently.

Sustainable Manufacturing is in Our DNA

Across Vietnam, India, Malaysia, and Indonesia, Laserhub Asia integrates sustainable practices at every level of production. From low-emission equipment to efficient process planning and renewable energy use, our approach is engineered to reduce environmental impact. We believe operational excellence includes environmental accountability, and we aim to be a long-term positive force in global manufacturing ecosystems.

Sheet Metal Housing and

Paneling Products

We produce OEM in Asia – housings and panels for machines and automation, built from durable materials to ensure reliable performance in tough industrial environments.

Electrification &

mobility

We supply custom sheet metal and die-cast parts for EV chargers, including frames, brackets, housings, and enclosures—produced through contract manufacturing in Asia.

Sheet Metal products for Food processing

OEM from Asia – We make stainless steel parts for food processing equipment, meeting hygiene and corrosion standards. Used in conveyors, mixers, and machines.

Sheet Metal Display Products

Contract manufacturing from Asia – We produce display frames, kiosks, and signage supports for retail and digital clients—precision metalwork with surface treatments.

Sheet Metal Enclosures Products

We deliver OEM from Asia – enclosures for electrical and control systems, built for indoor/outdoor use in various form factors and finishes—meeting client specs and safety regulations with reliable protection.

Frames for

furniture

We supply, through OEM contract manufacturing Asia, structural frames and supports for commercial and industrial furniture—blending strength, aesthetics, and cost-efficiency for desks, shelving, and other contract manufacturing needs.

Accessories for

vehicles

We make metal parts for motorbikes, cars, and utility vehicles—racks, mounts, guards, brackets, and frames—delivered under OEM and aftermarket projects, all tailored to customer requirements.

Construction

hardware

We supply fixtures, fasteners, brackets, and door/window systems for architectural use—produced under contract manufacturing in Asia to meet both functional and aesthetic requirements. Contact us now for more information!

Mounting – audio/tv Sheet Metal Products

OEM parts made in Asia – We make brackets, mounts, and supports for AV gear like speakers, amps, and TVs—built for strength, durability, and function, with surface finishes that meet the demands of high-performance setups.

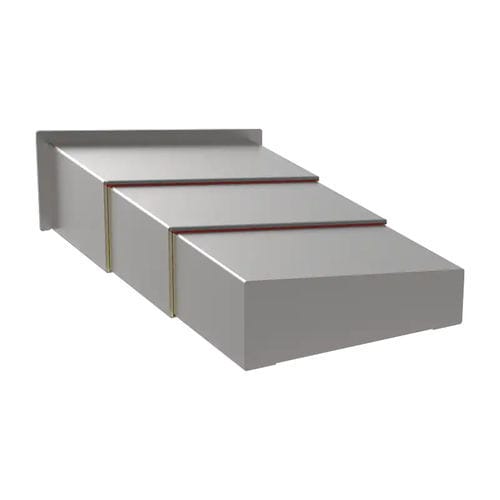

Handling

solutions

We supply heavy-duty frames and platforms for carts and trolleys in logistics, retail, healthcare, and manufacturing—engineered for contract manufacturing clients with focus on ergonomics, strength, and durability.

Sheet Metal

Motorbike accessories

Through OEM and contract manufacturing projects, we produce stamped, bent, and welded motorbike parts — including footrests, crash guards, accessory brackets, and frame components. Our focus is focused on quality.

Renewable

energy

We deliver metal mounting systems, brackets, and support frames solar installations. Manufactured as part of solar industry supply chains, these components durable, and resistant to harsh environments