The OEM and Contract Manufacturing Services of Laserhub Asia

OEM and Contract Manufacturing Services

Laserhub Asia provides end-to-end sheet metal services tailored for OEM production and contract manufacturing across Vietnam, India, Malaysia, and Indonesia. Our expert team and modern production technologies ensure scalable, high-precision fabrication for your components and assemblies.

OEM and contract manufacturing services in Asia

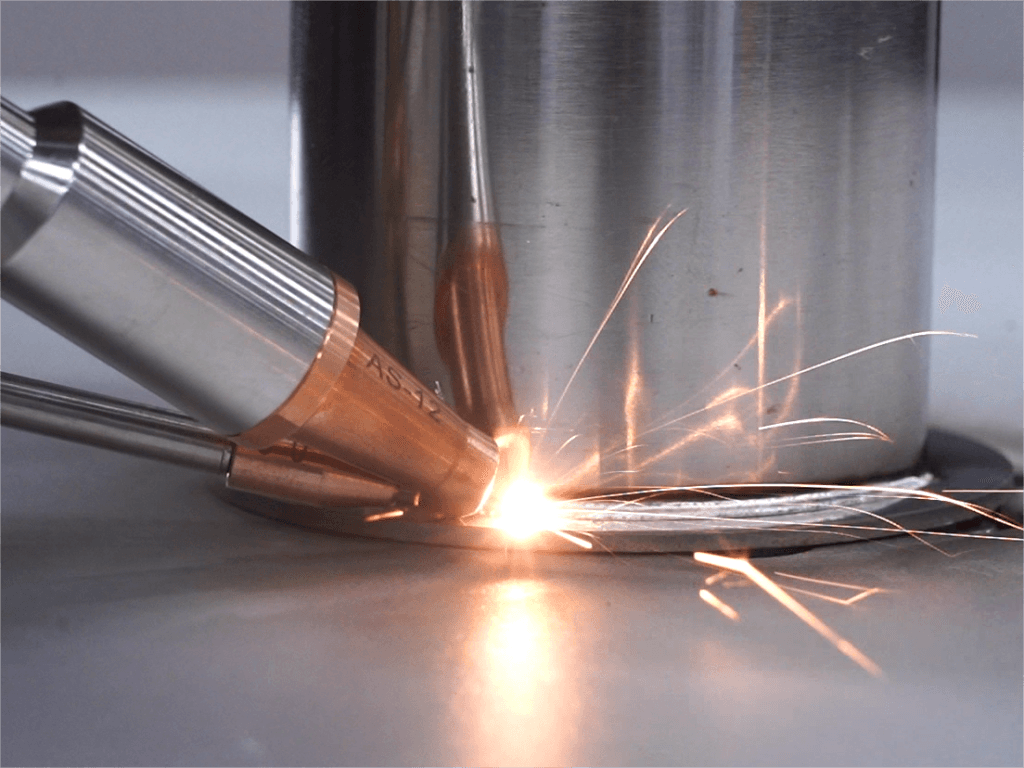

Laser Cutting

We use high-precision laser technology to cut sheet metal accurately and cleanly. Ideal for detailed or complex designs, this process minimizes waste while maintaining tight tolerances and sharp finishes—perfect for precision OEM parts.

Turret Punching

Our turret punching capabilities offer fast, flexible production for sheet metal components. With CNC-controlled punches and multiple tool heads, we can produce custom perforations and cutouts across a variety of sheet thicknesses.

Stamping

Our metal stamping service provides repeatable, cost-efficient shaping for high-volume production. Commonly used in the automotive, electronics, and appliance sectors, it ensures fast throughput and consistent part geometry.

Sheet Metal Bending

We use precision press brakes to shape metal into specified forms, ensuring accuracy and consistent angles for brackets, chassis, and structural parts used in industrial and consumer products.

Welding and Metal Joining

Our welding capabilities—including MIG, TIG, and spot welding—allow us to assemble components securely for structural strength or clean aesthetics. We work with various metals and joint types to suit all manufacturing needs.

Deburring and Edge Finishing

We perform precise deburring to eliminate sharp edges and surface burrs, improving safety and the finished appearance of parts. This step is especially important for visible or handheld components.

Tapping and Threading

We provide tapping services to create threaded holes in sheet metal, allowing for secure assembly with screws or bolts—ideal for modular designs and assemblies in many industrial applications.

Clinching

Clinching provides a hardware-free joining method that is efficient, clean, and reliable. Especially useful for lightweight or layered assemblies, it avoids heat distortion and maintains structural integrity.

Assembly Services

We assemble semi-finished and finished metal products ready for direct use or further integration.

Packaging and Logistics

We offer customized packing options for safe delivery of components and finished assemblies.

At Laserhub Asia, we are committed to environmental responsibility across all our laser cutting and metalworking operations. Serving a broad range of industries, we actively reduce our carbon footprint by adopting the most energy-efficient technologies available.

Sustainability is a core priority—not just efficiency. We apply lean and green principles to minimize waste, enhance resource utilization, and streamline our processes. As part of this effort, we have introduced a machine-level electricity monitoring program. This enables us to precisely measure and manage energy usage, drive continuous improvement, and reduce our overall environmental impact.

For more information to see how we manage our energy consumption please contact us or click on the following link to visit the website of https://vinergy.vn/.